What is Used in Making Automobile Parts

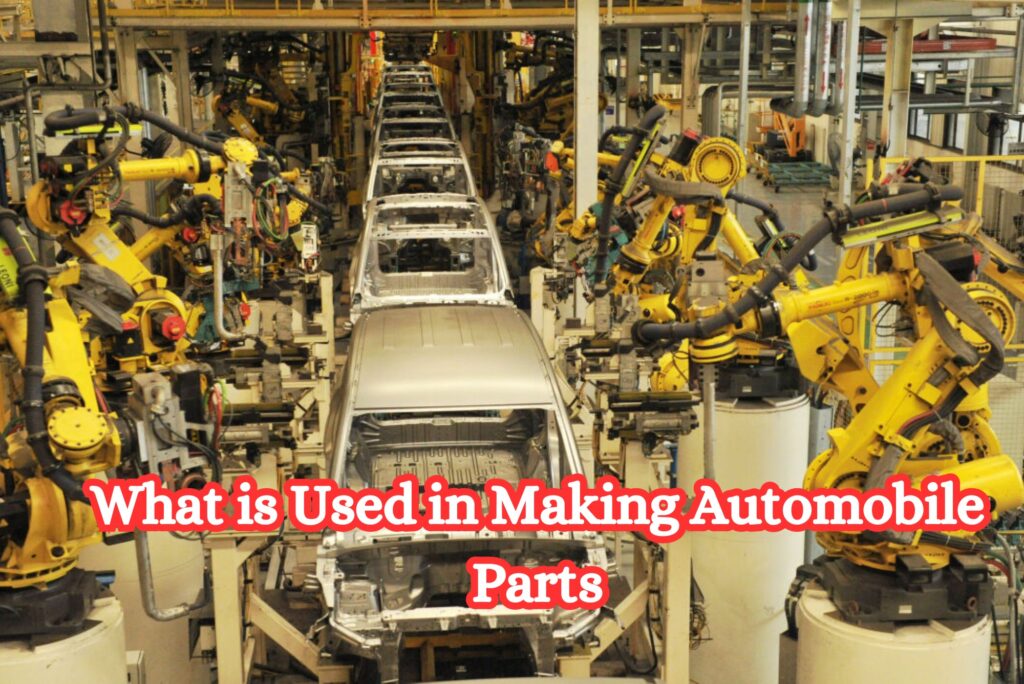

In the realm of automotive manufacturing, the materials used in crafting vehicle components play a pivotal role in determining the performance, safety, and durability of automobiles. From the robustness of metals to the versatility of plastics and the innovation of composites, each material brings its unique characteristics to the table. Let’s delve deeper into the essential elements utilized in making automobile parts.

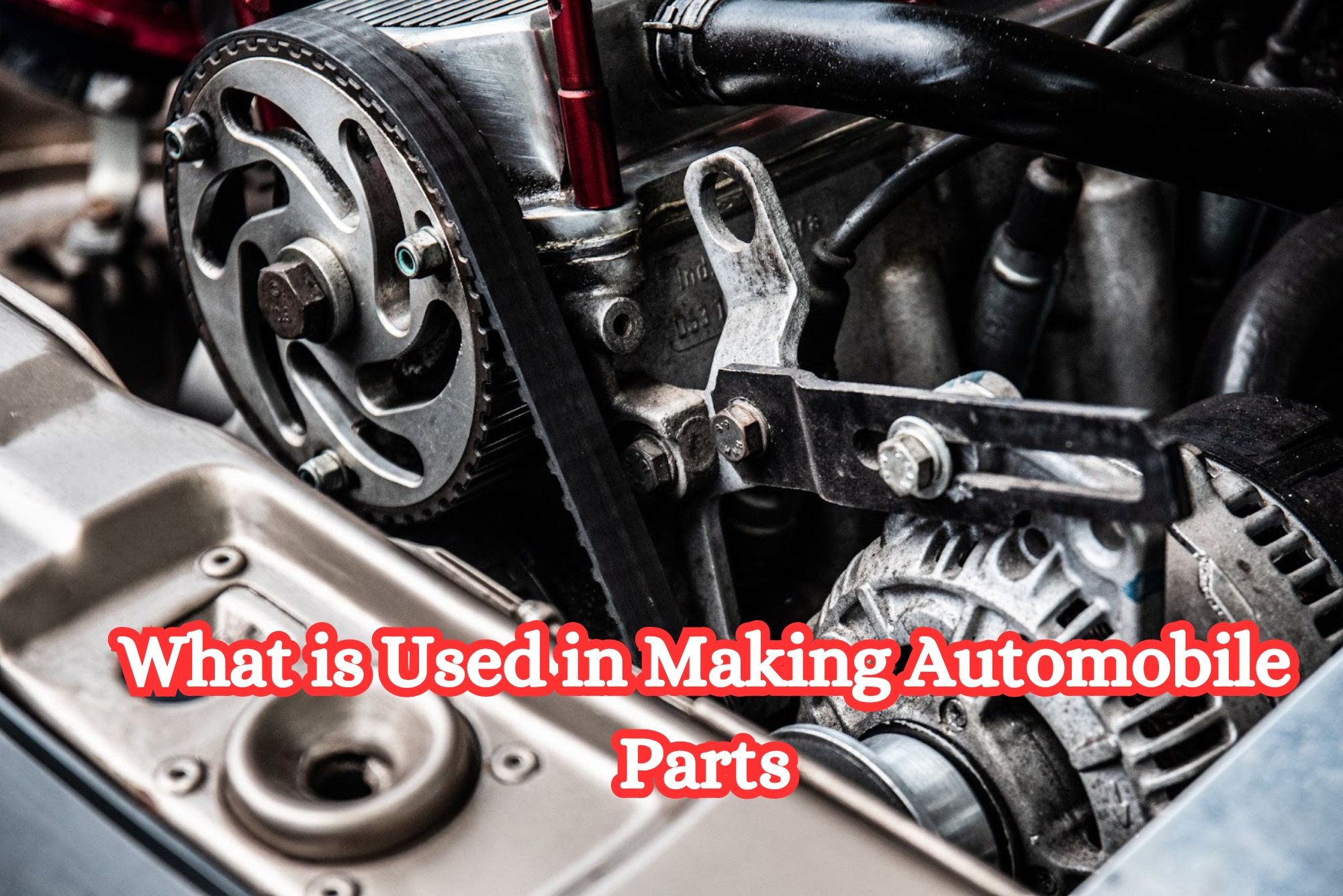

Metals: The Backbone of Automotive Engineering

Metals have long been the backbone of automotive engineering, owing to their strength, durability, and versatility. Steel, aluminum, and iron alloys dominate the landscape, with each offering distinct advantages. High-strength steel provides exceptional crash protection, while aluminum alloys contribute to lightweighting, enhancing fuel efficiency and performance. Iron alloys find their place in engine blocks and other structural components, ensuring robustness and longevity.

Plastics: Versatile and Lightweight

In recent decades, plastics have emerged as indispensable materials in What is Used in Making Automobile Parts manufacturing, owing to their versatility, lightweight nature, and cost-effectiveness. Polypropylene, polyethylene, and polycarbonate are widely used in interior components, such as dashboards, door panels, and trim pieces, offering designers ample freedom in aesthetics and functionality. Additionally, thermoplastics like ABS and PVC contribute to exterior parts, including bumpers, grilles, and body panels, where impact resistance and design flexibility are paramount.

Composites: Innovating Automotive Design

Composites represent the pinnacle of automotive material innovation, combining the strength of traditional materials with the flexibility of advanced polymers. Carbon fiber reinforced polymers (CFRP), fiberglass, and kevlar composites are revolutionizing automotive design by offering unparalleled strength-to-weight ratios, enabling the creation of lightweight, yet incredibly resilient components. From chassis structures to body shells, composites are reshaping the landscape of automotive engineering, pushing the boundaries of performance and efficiency.

In conclusion, the materials used in making automobile parts form the very foundation of automotive engineering, dictating the performance, safety, and sustainability of vehicles. From the time-tested reliability of metals to the versatility of plastics and the cutting-edge innovation of composites, each material brings its unique set of characteristics to the table, driving advancements in automotive design and manufacturing. As the industry continues to evolve, the quest for lighter, stronger, and more sustainable materials remains at the forefront, shaping the future of mobility.

Sedan Cars in India

Sedan cars in india hold a significant position in the Indian automotive market, offering a perfect blend of comfort, style, and performance. With their spacious interiors, refined driving dynamics, and sophisticated features, sedans cater to the discerning needs of Indian consumers. From compact sedans like the Maruti Suzuki Dzire to luxury offerings from BMW and Mercedes-Benz, the segment encompasses a wide range of options to suit diverse preferences and budgets.

Rafi Auto

Rafi Auto is a renowned name in the automotive industry, recognized for its commitment to quality, innovation, and customer satisfaction. Specializing in the manufacturing of precision-engineered automotive components, Rafi Auto caters to the needs of leading automobile manufacturers worldwide. With state-of-the-art facilities and a dedicated team of professionals, Rafi Auto continues to set new benchmarks in automotive excellence, driving progress and innovation across the global automotive landscape.